When the beta version arrived it was clear that a new standard in control had been set, and for some that is reason enough. However, lots of folks like a more neutral feeling binding, preferring to rely on their own technique to get them through the tough moments. A neutral flexing binding also means less fatigue on uphill climbs. The Hammerhead not only accommodates that, but when it also delivered randonnée-like freedom of the heel for skinning, the award was inescapable.

Many testers have commented that the Hammerhead will revolutionize telemarking. It seems a lofty statement, even if it does raise the bar for downhill control and uphill freedom in the same package. I’ll agree with the claim, but for different reasons.

Revolutionary Beta Test Program

The most revolutionary thing about the Hammerhead was the beta program that helped produce it. Rather than rely on “inside” testers Rainey took the Hammerhead public, asking customers to join the test team. Three hundred telemarkers paid full pop to give tons of feedback that allowed Rainey to pack 5 years of upgrades into the first revision. He also rebuilt a trust with customers that the SuperLoop had tarnised and while he was at it, built a word-of-mouth sales force 300 strong.

In 2001 the Hammerhead delivered unheard of freeheel control. It remains the standard by which other telemark bindings are judged for power.

Synthesis of Components

There is no single element of the Hammerhead that creates this increase in power. Instead, it is the combination of parts that add up to the dramatic change.

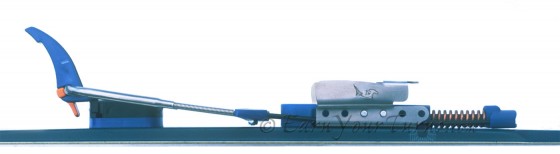

The Hammerhead consists of a single, 6 inch long compression spring underfoot, housed beneath a 21mm high shim. A block of plastic resembling the head of a hammerhead shark (hence the name) fits over the front of the spring. The cable runs around the front of this block, while both ends run back under the boot, inside two channels formed by a gap between the shim and the toe plate.

A wrap around stainless steel toepiece offers superb durability while adjustable cable pivot points let you adjust tele-resistance.

The spring allows a smooth, progressive engagement of spring tension and a full 2” (50mm) of travel, enough to prevent bottoming the spring out, and ripping the binding out of your skis; even for size 13 feet doing starfish turns.

Freedom of the Heel

By adjusting the cable guides to the front position you can attain a fairly neutral feel, or can get even more freedom by loosening the cable to be less snug and/or by completely removing the cable guides.

Adjustability

The Hammerhead requires no tools for adjustment. To move the pivots, push the locking button and slide the cable guide in the cable track. Okay in warm conditions, but I’d recommend a small screwdriver in the field to help push the pin in and perhaps to clear the path. Adjusting cable length is a matter of spinning the cable sheath going in to the heel. There is enough throw distance on the heel lever so that by making small adjustments in cable length you can quickly increase cable tension.

Complaints

While possible, and arguably easy at that, changing pivot points for more or less flex resistance still requires taking your skis off and fussing with the binding. Compared to any randonnée binding available in the U.S., it still has a ways to go for ultimate mode switching convenience. Nonetheless, it offers more range of motion and/or tension than any other telemark binding today.

Durability

The weak points are the push buttons on the cable guides; they’re notorious for wearing away, or enlarging the mating holes. Although the mounting area is dramatically increased to improve binding retention, so to are the forces it creates to rip it from a ski. My guess is you only need be concerned if you put the pivots way back and have large feet. Even at that, it’ll probably hold until you want to replace your old skis anyway.

22 Designs

Hammerhead

MSRP: $225 (original price was only $199)

Weight/pair: 3.2 lbs. (1451 g)

© 2001

This is a reprint of an article that first appear in Couloir Magazine Vol. XIV-1, Oct. 2001.

Epilog

In 2005, 22 Designs purchased Rainey Designs and continued producing the binding with very minor adjustments to the binding through 2012. They created a free-pivoting version of Hammerhead called Axl that maintained the same underfoot cable routing with easier to adjust power pivot points. The spring system was different than Hammerhead and in an effort to streamline sourcing costs the Vice telemark binding was created, effectively ending production of Hammerhead. It is one of the few, true, legendary telemark binding designs that had an effect on nearly every telemark binding design since its inception although its inventor, Russell Rainey, would be quick to point out even Hammerhead borrowed from other, less successful designs (the Pitbull), only with a better execution.

© 2012

5 comments

3 pings

Skip to comment form

Good times. Is the Vice coming out this year? I read the HH will still be sold this year but wondering if they will overlap.

The overlap will last as long as the parts for HH do…although 22D will definitely cut it off at some point so that they have an adequate supply of replacement parts for those who are sticking with HH until they die (not the binding, the skier) 😉

Hey Dostie, I’ve been searching for an answer to this (probably silly newbie) question but I really couldn’t find it anywhere. I’m totally new to dropping my knee this year, I bought 22D Hammerheads and Black Diamond Custom boots and am absolutely loving how they ski.

My question is, on the duckbill of the boots where the rear metal edge of the HH binding is, grooves have been worn into the plastic on each top side of the duckbill. I’ve only had them out for 4 days and they seem to be pretty deep (a couple mm). Is this normal? It seems unavoidable given the binding innterface, but it still concerns me to see so much wear after only a few days out. I searched and couldn’t actually find an answer to this, so I’m turning to you.

-Scott

In an ideal world that would not happen. My guess is the boots were ground a bit narrow (it doesn’t take much), allowing them to fit deeper into the wedge shape of the HH toeplate. I recommend you file down the back of the toe bale that runs across the top of the duckbill so that it no longer contacts the front of the toe. You shouldn’t need to remove more than 1mm of material and the HH toe bale is totally overdesigned. It can stand to be a bit less wide – especially if it is wearing your boots down.

On the durability front I have had a couple issues- two sliders cracked and had to be replaced (maybe just a bad batch out of the mold?), and I dinged the heel tube where the cable coils thread in, resulting in a pinched cable that I couldnt tighten or loosen. When I tried to tighten the cable coil into the heel tube with some pliers the coils just unwound, and nothing I or a friendly skitech could do would rewind the coils so they wouldwind into the heel tube. I ended up ordering two replacement cables because I can see this happening again if one of the coils gets kinked or dinged by a ski edge… so despite Rainey’s 300-strong testing force there are still some durability issues outstanding. That said, the Hammerhead is one heck of a binding, and I plan to continue using for a long time to come.

[…] © 2012 Share this:PrintEmailShareStumbleUponDiggRedditpinterest Posted in Telemark Bindings « Rerun: Rainey Design’s Hammerhead (v1) […]

[…] and delivers excellent skiing control. It combines the control of NTN with the smooth flex of a Hammerhead (Axl/Vice). Based on control and flex alone, the Mantis can be skied as an every day binding. […]

[…] The ratings in the table above are based on the Hammerhead scale, a cable binding developed by Rainey Designs with underfoot cable routing and adjustable […]