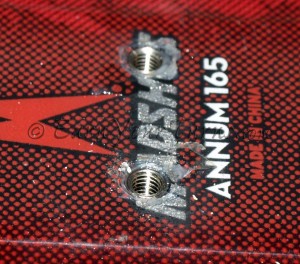

Inserts are one way to reduce the pulling forces on each screw by increasing the bonding surface area within the ski by using a larger diameter screw, i.e. an insert. This has the side benefit of allowing you to use a machine threaded screw to remove and connect hundreds of times with no loss in structural integrity or the strength of the connection.

Insert Costs

The price you pay for using inserts is higher material and labor costs. If you’re planning to swap bindings more than once using the same holes, inserts are a smart investment. If multiple times, or because you’re worried you might pull the bindings out in a fall or while tele skiing, they are mandatory. In all cases, if you think you will need inserts, you’re better off to do it with the original installation, rather than as a repair. There are several types of inserts. Heli-coils® are typically used to repair a rotted hole, or where the screw has been pulled out. These allow you to use the original mounting screw, threaded into the heli-coil insert. All other inserts work with machine threaded screws. Brass inserts are good for repairing a worn mounting hole, but are too soft to use for swapping bindings repeatedly since the threads could become damaged. For multiple use, stainless steel inserts are recommended, including Binding Freedom, Quiver Killer, and Keenserts®. Keenserts® come with kees that lock them in place, but are not sealed at the bottom. For that reason, and their exessive cost, inserts from Binding Freedom or Quiver Killer are the best choice for mounting ski bindings. In my experience the increased circumference of inserts adds the necessary holding power to prevent binding pull out. For telemarkers it is sufficient to only use inserts on the rear two mounting screws of the toeplate. In the long run, the benefits most certainly outweigh the costs as long as you’re willing to make the effort.Installing Inserts

Precise hole location is critical with inserts. The best way to achieve that is to use a mounting jig. In the absence of that, the reader is advised to apply the carpenter’s rule and proceed with extra caution. If a hole is off-center a bit with the standard ski core material (wood), the error can usually be tolerated, and is self correcting to some extent as the binding is mounted. With inserts that accept a machine threaded screw mismatches between the binding hole location and the insert location allow for very little error.

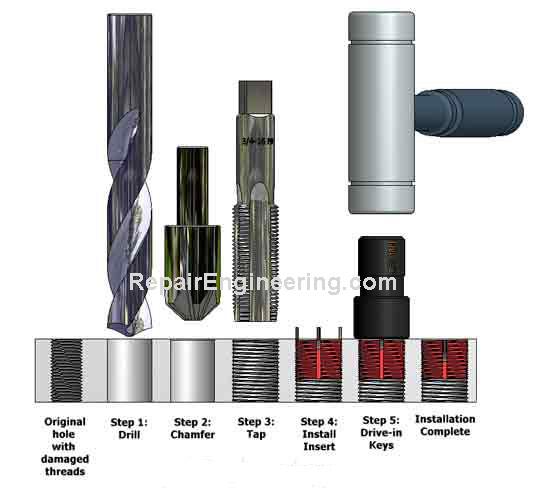

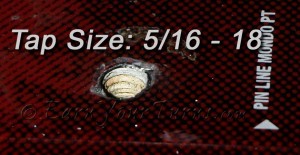

One way to minimize this possibility is to mount the binding with wood screws first to make sure all holes are aligned correctly. If so, then the original holes can be reliably expanded for an insert. It is possible to use a simple drill bit with tape on it to gauge depth, but it is best to use a stepped drill bit so you don’t drill too deeply. In the case of BF, QK, or Keenserts, use a 6.5×9.5mm stepped drill bit. It is still recommended that a mounting jig be used to prevent the drill bit from wandering off center in an existing hole. Once the holes are drilled for the insert be sure to thread the holes with the correct tap. For BF, QK, or Keenserts® use a 5/16” diameter tap with 18 threads per inch. (5/16-18).To keep the insert bonded in the hole, fill the threads in the hole with a slow cure epoxy. Then thread the inserts into the holes. Either use a special tool (available from QK or BF) or use a 5mm machine screw using two nuts to lock the screw position on the insert so it rotates with the screw. When the top of the insert is flush, or slightly below the surface of the ski, back the screw out. If the insert still moves with it, loosen the two locking nuts so the screw can move independent of the insert. The beauty of Binding Freedom inserts is you can use a simple flathead screwdriver to thread them in.

After threading the inserts into the holes, let dry for 24 hours, preferably in a warm room, not on the work bench in your cold garage.

Recommended screws

The question arises what length M5 screws to use. That depends on the binding being mounted. For telemark bindings the pan-headed screws that Voile and K2 provided with their skis that had inserts are the best, being roughly 12mm in length. The key thing to keep in mind is that you want the screw to have at least 3 threads of contact with the insert, preferably more. Adjust length accordingly.Thread Lock Options

Since this is a metal to metal threaded connection the chance of the screws coming loose is fairly high. Some sort of thread locker is recommended so the machine screws do not loosen from vibration. The most common recommendation is Blue Loctite® — apply the blue goo to the threads and let it dry before threading into the insert. I’ve heard of the blue goo working a little too well causing the insert to be removed when trying to remove the screw down the road. This is probably due to corrosion in combination with the holding power of the Loctite®. Vibratite® is my preferred thread locker. In my experience it will still allowing you to remove it later on, but that could be because I apply it circumferentially so it simultaneously seals out moisture. When I know I’m going to be swapping binding I have been known to use plumbers tape, not because it locks the screw in place, but because it seals out moisture. If you follow my advice with plumbers tape, be sure to check the tightness of the screws regularly and always carry a spare tool in your pack to tighten ’em up in the field.

Testimonial

In my experience I’ve never had a telemark binding come loose when I used inserts on the rear two toe piece holes. I use inserts for all my TTS cable posts to allow for changing cable positions without compromising the strength of the connection to the ski. Inserts are also used on my NTN bindings since different boot models require different sized NTN bindings. With inserts I can swap from a small to a large pair of NTN bindings in less than 10 minutes. That’s a little slower than using swap plates, but a lot lighter.

Related Posts and Links

BCTalk thread on installing inserts

Quiver Killer Inserts

Binding Freedom Inserts

Keenserts®

Aircraft Fastener threaded inserts

BackcountryTalk discussion: Inserts VS Helicoils

Installing Keenserts®

Installing inserts, e.g. Keensert®

© 2014

Recent Comments